A series of new technologies appear in the Mercedes-Benz factory in Vietnam

Mercedes-Benz has just released detailed information about 6 modern technologies that it has invested in its factory in Vietnam.

As the world’s leading car manufacturer, Mercedes-Benz is seen as a symbol of technological and technical advancement in the automation industry. The three-pointed star car company is constantly researching and improving the car manufacturing and assembly process to create the most desirable cars: luxury, safety and modernity.

Inherited from the most advanced technologies of the global production & assembly factory chain, Mercedes-Benz Vietnam wishes to take advantage of that outstanding advantage to gradually perfect the car production and assembly process in the near future. country. In the year 2021-2022, with a total investment of up to 33 million USD in the development of technical technology at the factory, MBV is affirming its strong commitment to sustainable development in the Vietnamese automobile market.

Mr. Klaus Schanz – Managing Director of Mercedes-Benz Vietnam Factory shared: “With this improvement, we can improve efficiency, product quality as well as flexibility on the production line of Mercedes-Benz Vietnam. yourself to a new level. At the same time, this is also an opportunity for our production force to have access to the latest technology through a training program by experts from the main Mercedes-Benz Group AG factory.”

Here are 6 new technologies of the Mercedes-Benz factory in Vietnam:

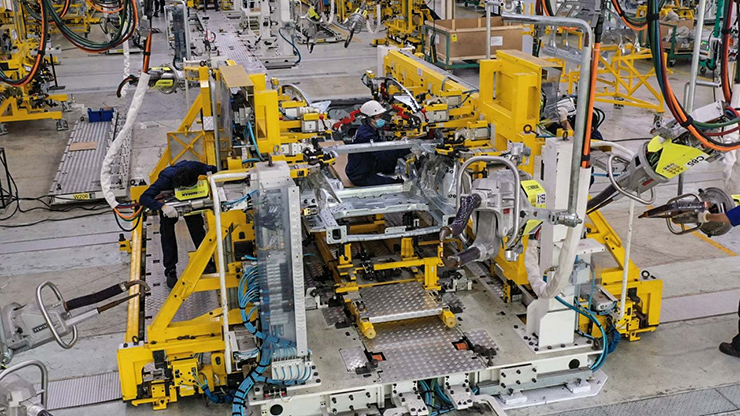

Line technology Integrated at Bodyshop, flexible up to 4 models: Body shop line is built on common platforms to optimize investment and reduce complexity. For the first time, MBV’s factory successfully applied a common body line for at least 3 car models (E-Class, GLC and C-Class).

This innovation ensures flexibility in the production process, and the line could expand production for a fourth (unspecified) model in the future. This is the first time this technology has been developed in a Vietnamese factory, marking an important step forward for MBV in completing the assembly line.

Robotic nail technology: Technological advancements have helped factories improve efficiency, production costs, and accuracy. As a result, Mercedes-Benz can now start using robots for key processes of body production for domestically assembled vehicles (CKD), to ensure efficiency and reliability. high precision.

With the working ability of Robot, now the factory can quickly weld more than 150 nail points within about 20 minutes on each robot station. This factor also creates an advantage for MBV in bringing new technology to domestic production lines, and at the same time training employees to familiarize themselves with and apply innovative features.

Eagle Eye technology to measure body geometry/coordinates (CMM): Eagle Eye technology helps to measure body geometry/coordinates at a micro-level, helping to reflect on systems and manufacturing processes on the chain. This technology ensures more accurate body measurements when performed on intricately designed planes as well as contours on the latest vehicle designs. Eagle Eye uses contactless measurement with an accuracy of up to 70 micro-meters, collecting nearly 1,900 measurement points.

Soundproof foam pump technology into the body (2K AFA Foaming): The soundproof foam pump technology introduced in the C-Class series is an advanced soundproof foam pump technology used to inject soundproof foam into the body. body compartments, in order to almost completely eliminate noise and enhance the road experience. This is the first time that MBV has brought this technology from the most advanced factories of Mercedes-Benz Group AG to the Vietnamese market.

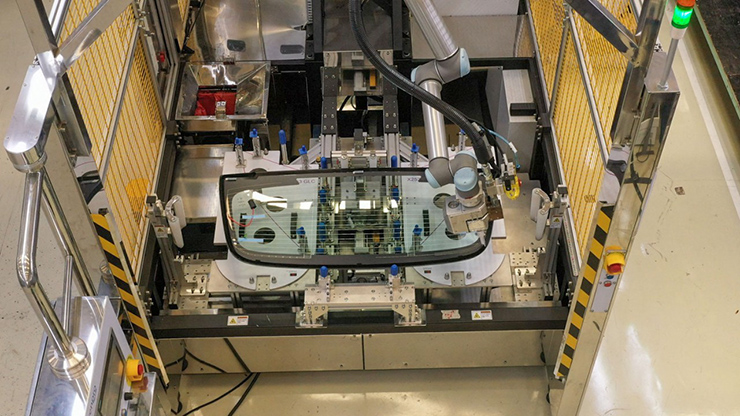

Robotic windshield glue injection technology: In the assembly process, the glue injection for the windshield depends a lot on the accuracy of the glue line on the glass circumference. This is a very precise step, so we are using robotic windshield glue technology in our vehicle assembly line.

Besides, the quality of glue will be improved when this technology is put into use. In fact, this technology has greatly improved the performance compared to the old technology and achieved almost absolute accuracy on the windshield surface.

Advanced undercarriage and powertrain technology: For the platform and future models, there have been improvements in chassis assembly technology. Due to a change in the design of the exhaust system, Mercedes-Benz will fit the entire powertrain with the bodywork (similar to those found in complete imported units (CBU) factories). Vehicles around the world will also be standardized.

These 6 new production and assembly technologies will mark the historic milestone of the MBV factory since 1995. The new C-Class that has just been launched in Vietnam will be the first model to apply these technologies. . This is not only a step forward in the gradual transition to automation, but also represents a powerful upgrade in improving quality, safety and user experience.

According to Ngoc Hoang (Vietnamese people)

at Blogtuan.info – Source: 24h.com.vn – Read the original article here